A custom ring begins as a feeling, an image you can almost see, but not quite touch. Maybe it’s an heirloom you’re reimagining, a proposal ring you’ve dreamed of for years, or a piece that needs to balance multiple stones with exacting symmetry. In those moments, “close enough” isn’t enough. You need clarity. You need precision. You need a way to see the future ring before it becomes permanent.

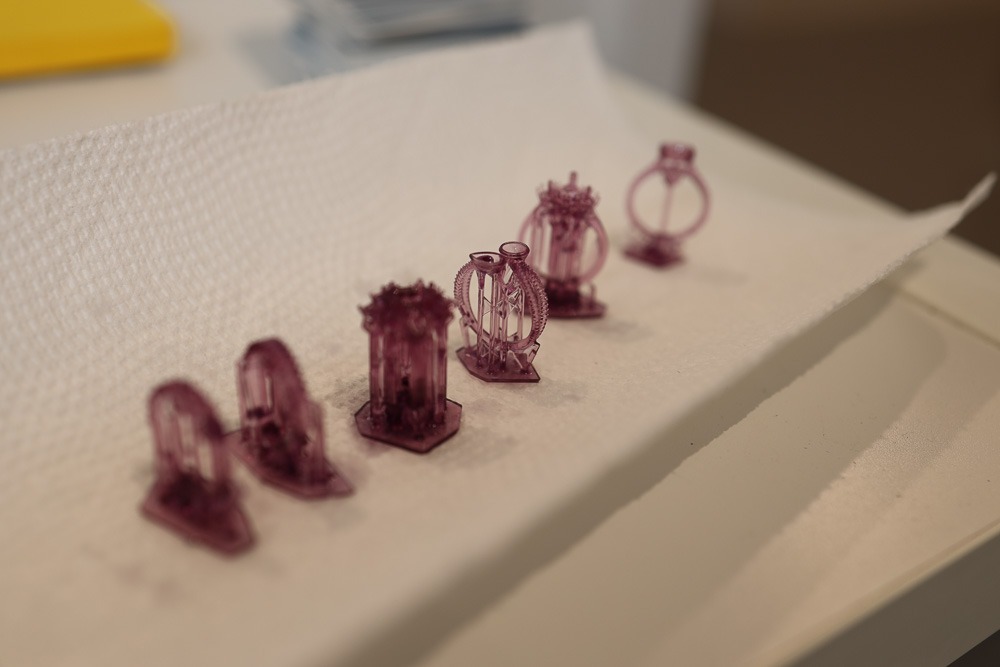

That’s where CAD and wax models step in. Computer-aided design and physical wax prototypes allow you to preview proportion, structure, and detail with extraordinary accuracy long before the metal is cast and the stones are set. Instead of guessing, you’re collaborating: refining angles, adjusting heights, and confirming that what lives in your mind will feel right on your hand.

At AW Jewelry, we treat CAD and wax models as instruments of assurance. They help us translate your story into engineered beauty so the ring you’re promised is the ring you receive, crafted with heirloom intention and technical precision.

How Do CAD and Wax Models Improve Custom Ring Precision?

CAD (computer-aided design) and wax models bring science to the service of sentiment. With CAD and Wax models, every curve, prong, and bezel is mapped digitally to fractions of a millimeter, ensuring that stones are seated securely, proportions are balanced, and the design is structurally sound. This digital file then becomes the blueprint for CAD and Wax models, a physical prototype you can see, hold, and experience from every angle.

Together, CAD and wax models reduce guesswork. You’re not just imagining how the ring might look; you’re previewing it. You can confirm how high the center stone sits, whether side stones feel too large, and how the band’s width feels in relation to your hand. For complex designs, heirloom resets, or pieces with significant emotional or financial investment, this level of precision becomes more than a step in the process; it becomes a safeguard for your Promise.

When Is CAD the Best Choice for Designing a Custom Ring?

CAD is especially powerful when your custom ring involves intricate details, unusual stone shapes, or structural complexity. If you’re working with a halo of many small stones, a multi-stone setting, or a very specific profile view, CAD allows every element to be measured and tested before anything is made. It’s also ideal when symmetry matters, think matched side stones, geometric designs, or clean modern lines that rely on flawless alignment.

CAD shines when you want to explore slight variations without starting from scratch. An artisan can quickly adjust band thickness, stone size, or prong style, and show you those changes in realistic renderings.

If you’re someone who likes to visualize all options before committing or if your ring incorporates valuable heirloom stones CAD gives you clarity, confidence, and the comfort of knowing the design has been engineered for both beauty and durability.

What Are the Benefits of Using Wax Models Before Casting a Ring?

Wax models make the design tangible before any metal is cast, offering both emotional and practical reassurance. They’re particularly helpful if you’re unsure how dimensions on a screen will translate to your hand in real life. Key benefits include:

Scale Check:

You can study the ring’s true proportions, its width, height, and overall presence to understand how it inhabits your hand. A wax model reveals whether the silhouette feels delicate or substantial, whether the center stone rises gracefully or appears too bold, and how the design interacts with the natural movement of your fingers.

Comfort Test:

Beyond appearance, you’ll feel how the ring rests between your fingers in everyday motion. The wax lets you test whether the profile feels too elevated, whether the band edges are gentle against the skin, and whether the overall balance supports the kind of comfort you want for daily wear. Comfort becomes a lived experience, not a guess.

Design Confirmation:

Intricate details become easier to evaluate in three dimensions. You can study the curve of the shoulders, the openness of the gallery, the contour of the band, and any hidden elements that might not translate fully in a digital rendering. The wax model shows how these details flow together, ensuring the final design aligns with both your aesthetic vision and the story you want the ring to hold.

Communication Clarity:

The wax serves as a shared language between you and the jeweler. Instead of relying on imagination or interpretation, you can point directly to the elements you love or the ones you’d like to refine. This clarity reduces misunderstandings, speeds up decision-making, and ensures the final piece reflects your intentions with precision and ease.

For those who value certainty before committing to a final casting, a wax model becomes a quiet but powerful step: a rehearsal before the main performance.

When Should I Insist on CAD and Wax Models for a Heirloom Reset?

If you’re resetting heirloom stones especially those with sentimental weight or unique cuts CAD and wax models are highly recommended. Older stones often have slight irregularities, and CAD allows the setting to be tailored precisely around those nuances, rather than forcing the stones into a generic mount. This preserves both the safety of the stone and the integrity of the design.

Wax models become invaluable here because you’re not just designing a ring; you’re stewarding family history into a new form. Seeing the ring’s architecture before the metals and stones are committed helps honor that legacy with care. If you’re combining stones from multiple pieces or reimagining a vintage style into something more current, CAD and wax models let you preview how these elements will coexist. In short, if the piece holds deep emotional lineage, precision modeling is a wise act of respect.

Are CAD and Wax Models Worth It for Simple Solitaire Designs?

Even simple solitaires can benefit from CAD and wax models though whether you “need” them depends on your preferences and priorities. If you’re dreaming of a very classic, minimal solitaire with standard proportions, an experienced jeweler may be able to bring it to life without extensive modeling.

However, if you are particular about the exact height of the stone, the angle of the prongs, or the thickness of the band, CAD and Wax models can help fine-tune these details. A wax model can then confirm how that subtle taper or precise shoulder shape feels on your hand.

Many clients who describe their style as “simple” still care deeply about nuance, and CAD and Wax models allow those nuances to be intentionally designed rather than left to chance. For an engagement ring you’ll wear daily, even minor refinements can make a meaningful difference in comfort and presence.

What Are the Pros and Cons of Using CAD and Wax Models for Custom Rings?

CAD and wax models offer powerful advantages, but it’s helpful to understand both sides before deciding.

Pros:

- Precision: Every dimension, from stone seats to band width, can be engineered with exactness.

- Visualization: Realistic renderings and physical wax models help you see the ring before it exists in metal.

- Flexibility: Adjustments are easier to make in the design phase than after casting.

- Security: Particularly reassuring for complex designs and heirloom stones.

Considerations:

- Time: The process can add steps and slightly extend the design phase.

- Cost: There may be additional fees associated with CAD work and wax models.

- Decision Overload: Seeing many iterations can sometimes make it harder for indecisive clients to choose.

For most, the reassurance and refinement these tools provide more than justify the investment especially for rings meant to last a lifetime.

How Do I Know If My Design Needs a CAD and Wax Model or a Hand-Sketch Is Enough?

It often comes down to complexity, precision needs, and your personal comfort level. A hand-sketch can be beautiful and effective for straightforward designs with familiar proportions. But when a ring involves complex architecture such as intricate galleries, layered halos, hidden details, or exact stone placements CAD becomes the clearest path to accuracy.

Consider CAD and wax if:

- You’re working with multiple stones, mixed shapes, or unusual layouts.

- You want to see several variations before choosing.

- You’re very detail-focused and prefer to approve specifics visually.

- The piece carries significant emotional or financial weight.

If you’re unsure, AW Jewelry’s Design Consultation Team can recommend the right path. Sometimes a design begins with sketching for mood and storytelling, then transitions to CAD and wax once the structure needs to be engineered, marrying artistry with precision.

How Does AW Jewelry Use CAD and Wax Models to Honor Both Design and Durability?

At AW Jewelry, CAD and wax models are not about making the process feel technical; they’re about protecting your promise. We use CAD to engineer every element: stone seats, prong angles, band thickness with both beauty and longevity in mind. From there, a wax model may be created so you can experience the ring’s presence before we commit to casting.

Our artisans review each design for structural integrity, ensuring the ring will stand up to daily wear, not just look stunning in a rendering. We invite you into that conversation, explaining the “why” behind certain design decisions so you feel informed, not overwhelmed. The result is a ring where the soul of your story meets the clarity of precision crafted as an heirloom, not an experiment.

When Should I Visit AW Jewelry to Explore CAD and Wax Models for My Custom Ring?

The best time to visit AW Jewelry for CAD and wax models exploration is when your idea feels emotionally ready but visually incomplete. You might have inspiration photos, a cherished stone, or a sense of the mood you want a ring that feels modern yet timeless, refined yet warm but you’re not sure how to translate that into exact dimensions and details.

Bringing your questions, sketches, or heirloom pieces into our studio allows us to listen first, then guide. Together, we’ll determine whether your concept calls for CAD, a wax model, or both. From engagement rings and anniversary bands to heirloom transformations, our role is to help you move from “I think this is what I want” to “I know this is the ring.”

Choosing CAD and wax models means choosing clarity, comfort, and confidence in a piece you’ll wear for decades.

Choosing to use CAD and wax models for your custom ring is choosing a path of intention, one where imagination and engineering walk side by side. When precision matters as much as sentiment, these tools help ensure the ring on your hand is the truest possible expression of what you envisioned.

If you’re ready to explore a custom design with that level of care, AW Jewelry would be honored to guide you. Visit our studio or connect with Client Services to begin shaping your ring through CAD, wax, and thoughtful collaboration so the Promise you design is the heirloom you’ll one day pass on.