Every heirloom begins as a small, human truth: I want this to feel like us. Custom jewelry is how that feeling finds a home in metal and stone. It’s not just “designing a ring”; it’s translating a story, a memory, or a promise into something you can wear every day.

At AW Jewelry, custom work moves from quiet conversation to CAD design, from wax model to molten metal, from rough casting to a finished piece that feels like it has always belonged to you. CAD is simply one of our tools, an instrument of precision that lets us honor your story with engineering-level clarity.

If you’ve ever wondered how custom jewelry is crafted from CAD design to heirloom, or what actually happens behind the studio door, this guide walks you through the steps in a calm, conversational way.

How Does My Personal Story Become a Custom Jewelry Design, Starting from the First Conversation to the Initial Sketch?

It begins with stillness and an unhurried conversation where we listen for the heart of your story. We ask gentle questions about who the piece is for, what moment it marks, and how you want it to feel in daily life. We’re listening for emotion, for symbolism, for the small truths that give a piece its soul.

From there, we translate those details into early sketches. These aren’t rigid or final; they’re soft interpretations of your words shapes, proportions, and gestures that begin to resemble the promise you’re making. We refine these sketches with you, adjusting what feels too bold or too quiet, until the silhouette begins to feel like something that belongs to your life.

When you can look at a sketch and say, “Yes, that feels like us,” the design is ready to move into CAD, where precision begins to take shape.

What Is CAD in Custom Jewelry, and How Does AW Jewelry Use It to Turn Emotion and Intention into a Precise, Buildable Design?

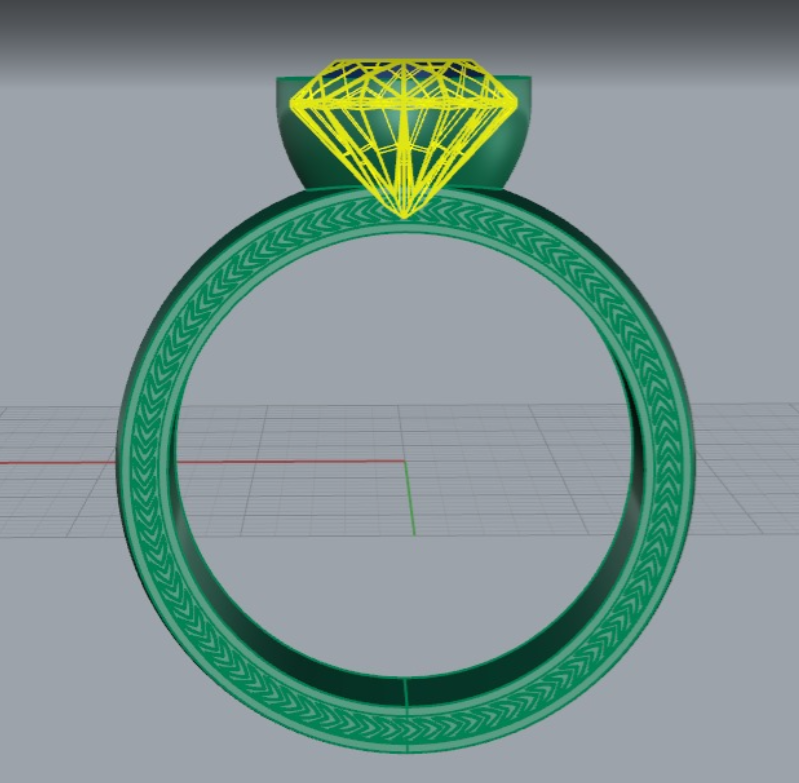

CAD is where your story gains structure. While sketches honor the emotion of your piece, CAD brings clarity mapping each curve, angle, and millimeter with engineering-level precision. At AW, we treat CAD not as a technical detour, but as a way to protect your vision.

In CAD, we can refine proportions so the piece looks balanced from every angle. We shape prongs and bezels to cradle your stone securely without losing grace. We check the inner architecture comfort-fit curves, band thickness, and weight distribution so the piece feels natural on your hand for decades.

Most clients love this stage because it turns imagination into something you can “see” from every viewpoint. You’re not guessing; you’re previewing. And when CAD feels right, we know the piece will cast beautifully in metal and remain steady through a lifetime of wear.

Which Design Details Like Stone Height, Balance, and Long-Term Wearability Are Refined Most Effectively During the CAD Stage?

Stone Height & Presence:

The height of the center stone determines how grounded or lifted the ring feels on the hand. In CAD, we can test exactly how high the stone should sit balancing everyday comfort with the sense of lift or openness you want. This is where we make sure the ring won’t snag easily and still carries the presence you envision.

Overall Balance & Proportions:

Balance is more than symmetry; it’s the visual harmony of the ring from every angle. CAD allows us to study the top view, the profile, and the hidden internal architecture beneath the stone. This ensures the ring looks intentional whether someone is admiring it from above or seeing its silhouette in motion.

Band Thickness & Taper:

A band must feel refined, not fragile. During CAD, we shape the thickness and taper so the band feels elegant on your hand while remaining strong enough for decades of daily wear. Even a fraction of a millimeter can shift the entire feel of the piece, so this stage gives us the precision needed.

Comfort-Fit Interior:

Comfort is engineered, not guessed. The CAD stage lets us sculpt the inner curve of the band so it glides on smoothly and sits naturally through long days. The comfort-fit interior is often the detail clients appreciate most once the ring becomes part of their daily life.

Prong & Bezel Engineering:

Prongs and bezels are where protection meets grace. CAD helps us build these elements with exacting care strong enough to guard the stone, but shaped with delicacy so they never feel heavy or bulky. This is the architecture that keeps your stone secure for years without compromising the silhouette.

Gallery Design & Light Flow:

The gallery under the structure of the ring determines how light moves through the stone and how the piece breathes. With CAD, we can sculpt openings, curves, and supports that give the ring its inner beauty. This is where a piece begins to feel like an heirloom from the inside out.

Stone Clearance & Band Pairing:

If you’re wearing a wedding band or stacking rings, CAD lets us calculate the exact clearance needed for a flush or near-flush fit. We adjust height, angles, and under-arches so the rings meet comfortably, gracefully, and without gaps creating a clean, intentional pairing.

CAD is the moment where every “how will this feel over time?” question becomes answerable, visible, and adjustable before metal makes anything permanent.

Why Is Reviewing a Wax or 3D Model Important, and How Does It Help Me Understand How My Future Heirloom Will Feel on the Hand?

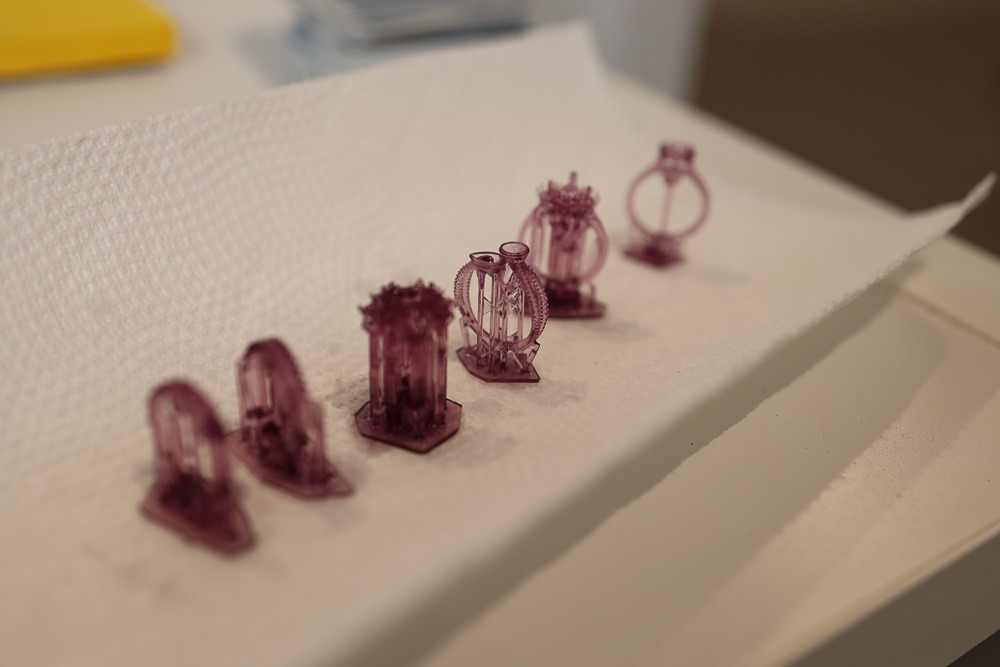

Holding a wax or 3D model is often the moment when the piece becomes real. On a screen, everything feels conceptual; in your hand, scale and presence finally make sense. You can see how tall the stone sits, how the band moves between your fingers, and how balanced the proportions feel with your hand’s shape.

It also reveals subtle details the eye can’t interpret through a digital rendering: the softness of a taper, the fullness of the shoulders, the way light travels through openings in the gallery. Clients often say this moment brings a kind of calm reassurance that the heirloom they imagined truly fits them.

And if something feels slightly off, this is the most graceful moment to adjust. A millimeter here or a softened curve there often brings the entire piece into harmony before it’s cast in metal.

What Happens During the Casting Process, and How Does My CAD Design Transform into Gold or Platinum at AW Jewelry?

Casting is a quiet transformation the moment your design steps out of the digital world and into metal. First, your wax or 3D model becomes part of a mold. When that mold is heated, the wax melts away, leaving a precise cavity that reflects every contour of your design.

Molten metal 18k gold or platinum is then poured into this space, filling every channel and curve. Once cooled, the mold is broken apart, revealing a raw casting. It’s not yet delicate or luminous; it’s the architecture of your heirloom, waiting for touch.

From there, our bench jewelers begin the meticulous refinement: smoothing the surfaces, shaping the inner curves, and preparing the setting to welcome its stones. Casting is where promise becomes substance, but it’s the human hands that follow that give the piece its soul, softness, and final balance.

How Do AW Jewelry’s Bench Jewelers Shape, Set, and Finish a Custom Piece?

AW bench jewelers move with the intention of stewards shaping a piece that will live on a hand, not just in a box. They begin by refining the raw casting, removing any marks left from the mold and smoothing the inner surfaces so the ring feels soft the moment it slips on.

Stone setting is both engineering and intuition. Each prong is shaped, placed, and tightened to hold the stone securely while maintaining grace. Bezels are smoothed and burnished, and galleries are refined so light moves through the piece with quiet elegance.

Once stones are set, finishing brings the ring to life. High points are polished to capture light; inner curves are softened for comfort; textures are refined where character is desired. The goal isn’t mirror shine, it’s balance, beauty, and longevity, ensuring your heirloom feels familiar from the first day.

How Long Does Custom Jewelry Take from the First Sketch to the Final Heirloom, and What Factors Influence That Timeline?

- Discovery & Sketching (1–2 weeks): This is where we listen, sketch, and refine until the shape feels like your story.

- CAD Design & Revisions (1–3 weeks): Timing depends on how many adjustments you’d like. Even micro-refinements matter.

- Wax/3D Model Review (1 week): Some clients decide quickly; others prefer to live with the model a bit longer.

- Casting, Setting & Finishing (3–6 weeks): Complexity, stone sourcing, and unique details shape this phase.

The entire journey typically spans 6–12 weeks. What matters most is that nothing is rushed. Each step is tuned to both craftsmanship and the rhythm of your milestone. We’d rather deliver a piece a week later and know it’s perfectly balanced, secure, and worthy of decades than rush a promise meant to last a lifetime.

How Does AW Jewelry Care for My Custom Piece Over Time, and What Does Long-Term Heirloom Stewardship Look Like?

Heirloom care is a long-term promise, not a quick service appointment. At AW, we see your piece as something living, worn, loved, and carried through daily life. Over the years, we welcome clients back for what we call Legacy Care, a gentle, ongoing stewardship of the piece we helped you create.

We inspect prongs and bezels to ensure stones remain steady. We clean with methods that respect both metal and gemstones, never harsh shortcuts. Finishes are refreshed with intention, restoring the soft matte glow or quiet polish that originally defined the piece. If a stone is ever chipped, loosened, or lost, we recalibrate or replace it while preserving the rhythm of the original design.

This ongoing relationship is our way of saying: your heirloom doesn’t just leave our hands, it stays under our care as it moves through every chapter with you.

Custom jewelry is not a product; it’s a process of conversation that moves from story to sketch, from CAD design to wax, from raw casting to heirloom. Along the way, choices about metal, stones, and setting styles are all tuned to one central question: What promise are we honoring, and how should it feel to wear it every day?

At AW Jewelry, we believe in promises built to last, symbols crafted with quiet precision, and pieces that feel like they could have been inherited or will be, one day.

If you’re ready to explore how your story might look in metal and stone, we’d be honored to begin that conversation whether in our studio or through a calm, online design session. Together, we’ll shape a custom piece that doesn’t just mark a moment, but becomes part of the life that follows.